YEMA,

Always moving forward.

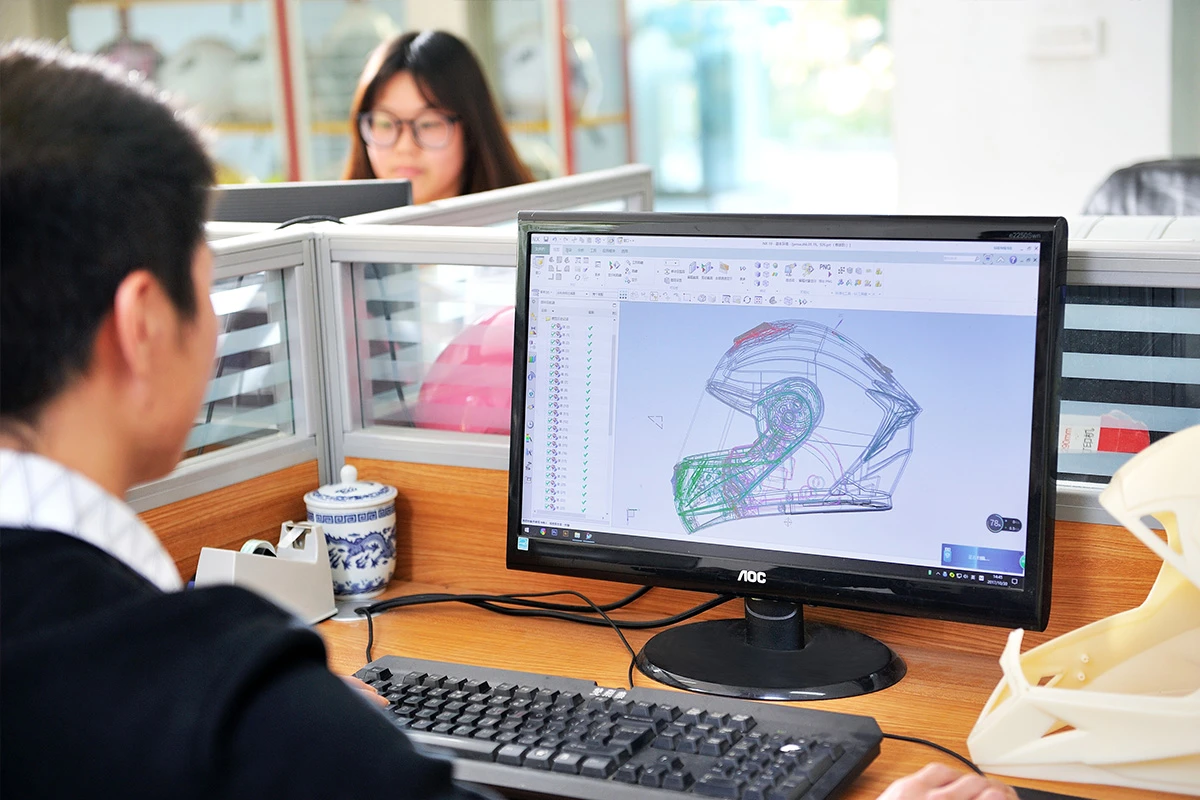

The YEMA technical team has over 30 years of product development experience, based on international professional design software and modeling systems, constantly innovating and iterating on styles, materials, and functions. Wild Horse has various technical research and development departments, including professional material research and development laboratories, mold development centers, impact mechanics research centers, and safety quality inspection centers.

The YEMA factory covers an area of 65000 square meters and includes a complete set of production lines for injection molding, substrate, painting, assembly, etc., with an annual production capacity of 4 million helmets.

YEMA helmets include hundreds of products in several categories, including full face helmets, half face helmets, off-road helmets, facelift helmets, children’s helmets, etc. They are made of mainstream materials such as ABS, PC alloy, fiberglass, carbon fiber, etc., and cover various uses such as electric vehicles and motorcycles.